Discover a wide range of materials to bring your creations to life

At Drükfab, material is not just a support; it is the soul of every creation.

That’s why we offer you a carefully curated selection of filaments, suited to your ideas, your needs, and your unique way of seeing the world.

Each material has its own personality, texture, strength, and story. And we are here to guide you, to find together the one that will give your project strength, precision, and character.

PLA, PETG, ABS, flexible, technical… We don’t sell filaments. We offer possibilities.

Because at Drükfab, innovation is born from the material… but also from the connection we build with you.

PLA: A versatile and eco-friendly material

PLA (Polylactic Acid) is one of the most popular materials in 3D printing, valued for its ease of use and reduced environmental impact. Made from renewable resources like corn starch or sugarcane, it is a more sustainable alternative to traditional plastics.

Why choose PLA?

✔ Quality finish: Produces prints with precise details and a smooth surface

✔ Wide variety of colours and effects: Available in many shades and finishes

✔ Eco-friendly: Biodegradable under industrial conditions and made from renewable sources

PLA applications

PLA is perfect for creating decorative objects, prototypes, figurines, architectural models, and more. However, it is less suitable for parts exposed to high mechanical or thermal stress, as it is sensitive to heat and moisture.

| Impact resistance | 26,6 KJ/m² |

| Flexural strength | 76 MPa |

| Stiffness | 2750 MPa |

| Layer adhesion | 13,8 KJ/m² |

| Heat resistance | 57 °C |

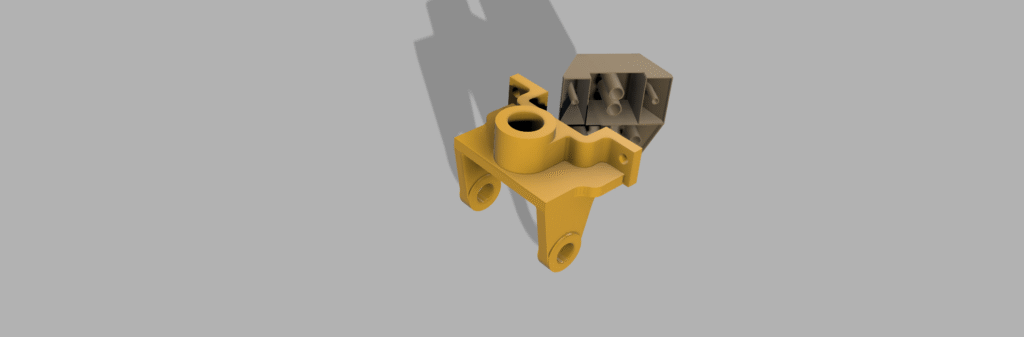

ABS: A strong material for durable parts

ABS (Acrylonitrile Butadiene Styrene) is known for its resistance to impact, heat, and wear, making it an excellent choice for strong and functional parts. Used in the automotive and electronics industries, and even for toys like LEGO, it’s ideal for demanding applications.

Why choose ABS?

✔ Strong and durable: Perfect for mechanical and functional parts

✔ Heat-resistant: Does not deform easily with heat

✔ Impact-resistant: Suitable for parts under repeated stress

✔ Finish options: Can be sanded, painted or chemically smoothed for a professional look

ABS applications

ABS is ideal for:

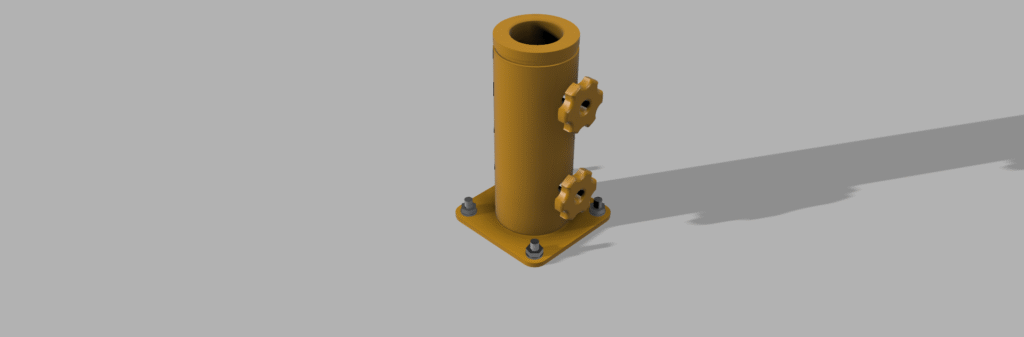

🔹 Mechanical and technical parts

🔹 Casings and protective shells

🔹 Functional prototypes

🔹 Objects requiring high strength and a refined finish

| Impact resistance | 39,3 KJ/m² |

| Flexural strength | 62 MPa |

| Stiffness | 1880 MPa |

| Layer adhesion | 7,4 KJ/m² |

| Heat resistance | 87 °C |

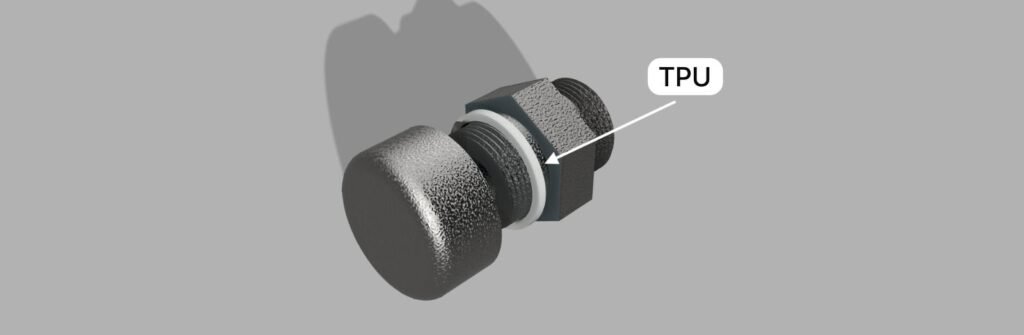

TPU: Flexibility and resistance for adaptable prints

TPU (Thermoplastic Polyurethane) is a flexible and durable material, ideal for parts that need elasticity, strength, and shock absorption. Its rubber-like appearance allows it to bend and return to shape without breaking, making it perfect for technical and functional applications.

Why choose TPU?

✔ Flexible and elastic: Bends and returns to shape without cracking

✔ High impact resistance: Absorbs shocks and vibrations

✔ Resistant to chemicals and abrasion: Suitable for demanding environments

✔ Non-slip and grippy: Ideal for grips, soles, and protective parts

TPU applications

TPU is commonly used for:

🔹 Seals, bellows, and dampers

🔹 Protective cases and shockproof covers

🔹 Soles, handles, and ergonomic grips

🔹 Flexible components requiring high durability

| Impact resistance | 123,2 KJ/m² |

| Flexural strength | Filament flexible |

| Stiffness | Filament flexible |

| Layer adhesion | 86.3 KJ/m² |

| Heat resistance | 57 °C |

PETG: Strength, precision, and reliability for durable prints

PETG (Glycol-Modified Polyethylene Terephthalate) is a rigid and durable material that combines the strength of PLA with the resilience of technical plastics. It offers excellent dimensional stability, resistance to moisture and chemicals, and is less brittle than PLA.

Why choose PETG?

✔ Strong and robust: Ideal for mechanically stressed parts

✔ Good impact and tensile strength: Suitable for technical and structural objects

✔ Waterproof and moisture-resistant: Perfect for water-exposed parts

✔ Easy to print: Less warping than ABS, good layer adhesion

PETG applications

PETG is often used for:

🔹 Durable mechanical and technical parts

🔹 Containers, casings, and components exposed to moisture

🔹 Structural supports or load-bearing elements

🔹 Outdoor or semi-outdoor parts exposed to wear

| Impact resistance | 52,7 KJ/m² |

| Flexural strength | 65 MPa |

| Stiffness | 1670 MPa |

| Layer adhesion | 13,6 KJ//m² |

| Heat resistance | 69 °C |

ASA: UV resistance and durability for outdoor parts

ASA (Acrylonitrile Styrene Acrylate) is a technical material known for its exceptional resistance to outdoor conditions. It retains its mechanical properties and appearance even after prolonged exposure to sun, rain, or wind. It’s a great alternative to ABS with better UV resistance and dimensional stability.

Why choose ASA?

✔ Excellent UV resistance: Doesn’t yellow or degrade in sunlight

✔ High durability: Suitable for technical and long-lasting parts

✔ Weather-resistant: Ideal for outdoor applications

✔ Dimensional stability: Minimal warping during printing

ASA applications

ASA is often used for:

🔹 Outdoor parts exposed to sun and weather

🔹 Electronic casings, covers, and automotive components

🔹 Urban or garden furniture elements

🔹 Technical prototypes needing strength and longevity

| Impact resistance | 41,0 KJ/m² |

| Flexural strength | 65 MPa |

| Stiffness | 1920 MPa |

| Layer adhesion | 4,9 KJ/m² |

| Heat resistance | 100 °C |

Why Choosing the Right Material Is Essential in 3D Printing

When undertaking a 3D printing project, design is certainly important. But what truly ensures that your part will perform its function over time is, above all, the material used. Too often, this choice is treated as secondary, when in reality it should be a top priority. Why? Because each material has its own properties, advantages, limitations, and most importantly, recommended uses.

Whether you’re creating an everyday object, a technical part, a decorative accessory, or an outdoor component, the right filament can make all the difference between a successful project and an unusable part.

A material for every use

Each material used in 3D printing has specific characteristics: strength, flexibility, heat resistance, exposure to chemicals, sunlight exposure, etc.

The right choice is not made randomly. It depends on the actual use you will make of the object.

Simply ask yourself these questions:

- What will the object be used for?

- Will it be handled frequently?

- Will it need to withstand weight, pressure, or impact?

- Will it remain outdoors?

- Should it be flexible? rigid? aesthetic?

From there, we can guide you towards the appropriate material.

Common mistakes... and their consequences

Case 1: The wall mount in PLA

A client wanted a small wall hook to hang items in a kitchen. They chose a PLA filament, attracted by its clean appearance. But just days after installation, the hook deformed and broke.

Why?

Because PLA, although rigid, cannot withstand heavy loads or the ambient heat of a kitchen.

The right choice would have been a PETG filament or a reinforced polymer, capable of resisting heat and mechanical stresses.

In the following photos, the PLA part on the left shows heat-induced deformations, while the PETG one on the right remained intact under the same conditions.

PLA

PETG

Case 2: The drawer handle in ABS

A client ordered a custom drawer handle for a workshop. The design is robust, and the print was done in ABS, known for its strength. But after a few weeks, the handle became smooth, slippery, and slightly sticky to the touch.

Why?

Because although ABS is impact-resistant, it reacts poorly to certain environments: solvents present in the workshop and prolonged exposure to UV rays degraded it.

The right choice would have been: an ASA filament, designed to resist chemical attacks and UV rays, ideal for technical or outdoor use.

In the following photos, the ABS part on the left shows heat-induced deformation, while the ASA part on the right remained intact under the same conditions.

ABS

ASA

At Drükfab, we fully understand that choosing the right material is not always straightforward. Each use comes with its own constraints: heat, humidity, mechanical stress, outdoor exposure… That’s why we support our clients in making this choice by offering the solution best suited to their actual needs. Our role is to guide you toward the best option, combining performance, durability, and aesthetics.