Discover our technology and the operation of 3D FDM printing.

The 3D printing process.

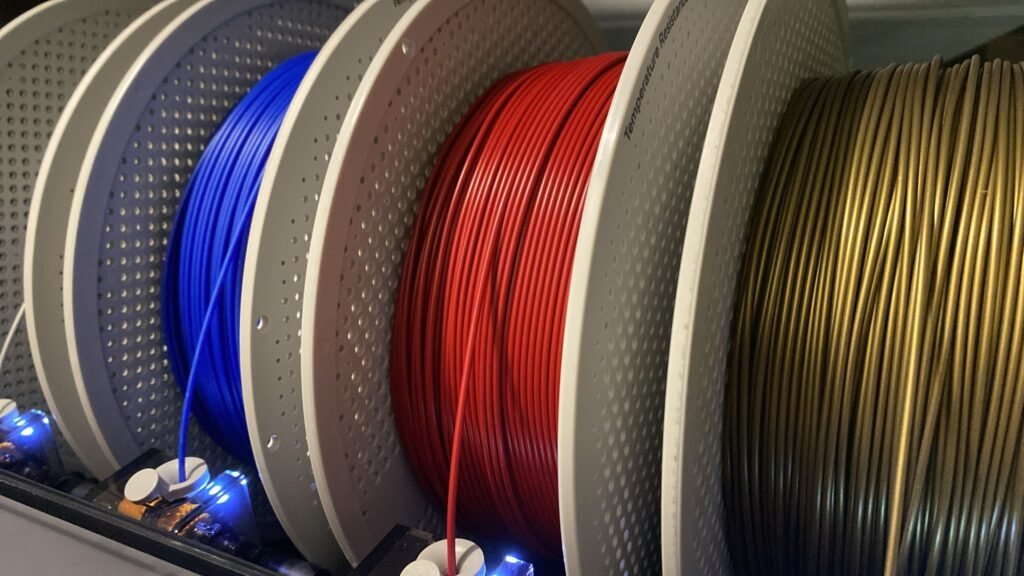

FDM 3D printing (Fused Deposition Modeling) begins with the selection of the plastic filament, which resembles a long wire. This plastic filament is the material we use in 3D printing.

Step 1: The choice of filament

The filament is a special plastic that is heated to become liquid and is deposited in very thin layers. There are different types of filaments (such as PLA, ABS, or PETG), each with specific properties such as rigidity, flexibility, or heat resistance.

Step 2: The role of the 3D printer

For the printing to work, a 3D FDM printer is needed, which heats the filament to a very high temperature. Each 3D printer consists of two main elements:

The print head, which heats and melts the filament.

The base, on which the object will be built.

Step 3: How FDM 3D printing works

Once the filament is heated and melted, the print head deposits it precisely on the base. This process is done layer by layer. Each layer is very thin, almost imperceptible to the naked eye.

When the first layer is deposited, the print head slightly lifts to move to the second layer, and so on. Each new layer bonds to the previous one, gradually creating your object.

Why choose FDM technology?

FDM technology allows the creation of solid, durable, and customized objects quickly and at a low cost. It is an ideal solution for prototypes, unique parts, or small production runs.

How do we guarantee print quality?

At Drükfab, quality does not depend solely on the technology used, but above all on the constant attention given to maintaining our equipment. It is this rigor that allows us to deliver precise, clean, and durable parts, print after print.

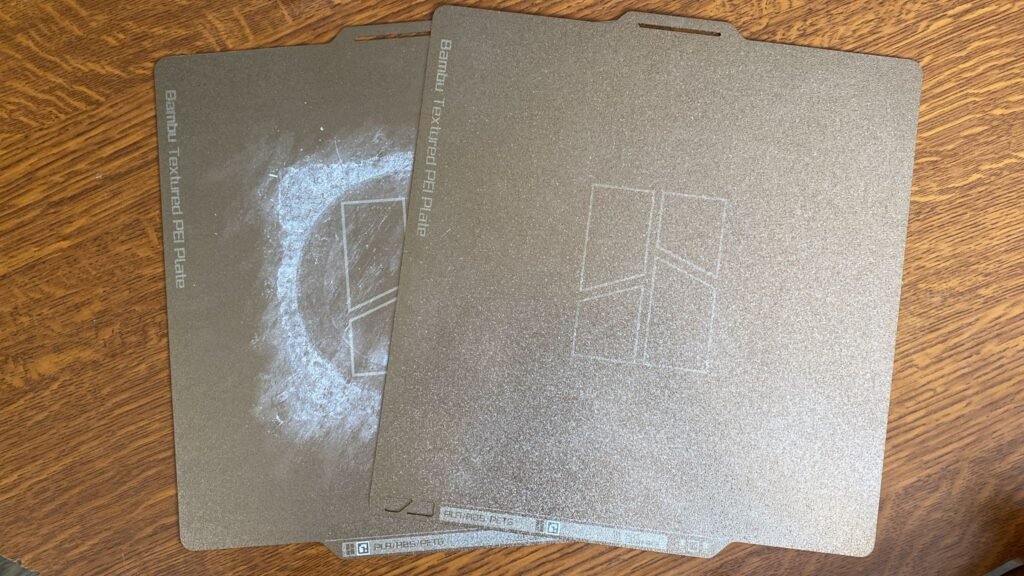

Regular preventive maintenance

Each printer in our fleet undergoes a preventive maintenance plan. This includes:

daily cleaning of nozzles, print beds, and extrusion systems,

checking the tension of belts and guide screws,

inspecting sensors and electronic components,

as well as regularly updating firmware to ensure optimal performance.

This systematic monitoring helps prevent premature wear of components, axis misalignments, or extrusion errors that could compromise the final quality.

Checks before each pint

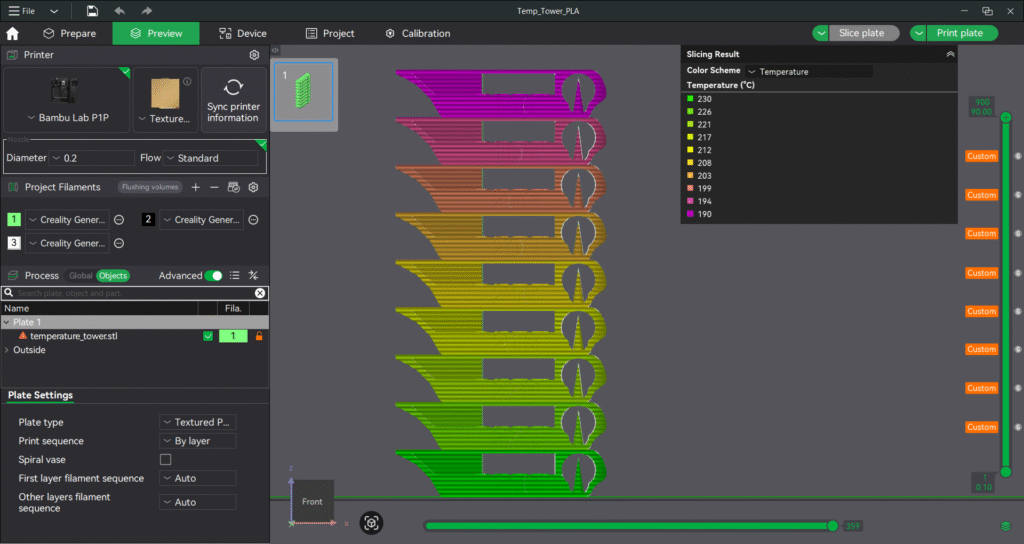

Before each project, a thorough check is performed:

Bed calibration for a perfect first layer,

Temperature and filament flow test,

Visual inspection of the nozzle and cooling system.

These steps ensure that every print starts under the best possible conditions.

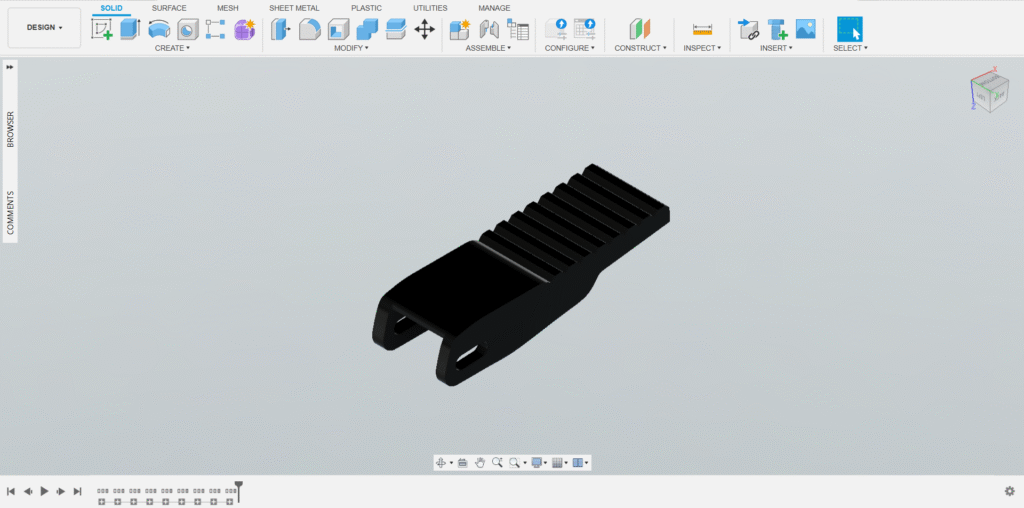

Quality behind the modeling

Even before the part is printed, much of the work takes place on the computer. At Drükfab, we pay special attention to this crucial step because it largely determines the precision, strength, and success of the print.

Custom 3D Modeling

Each project starts with a clean, sturdy, and functional 3D model. Whether the client provides the file or we design it ourselves, we ensure that it is:

geometrically clean (without mesh errors, non-manifold surfaces, or floating elements),

dimensionally consistent with the intended use,

optimized for printing, with wall thicknesses, angles, and shapes designed to prevent warping or printing errors.

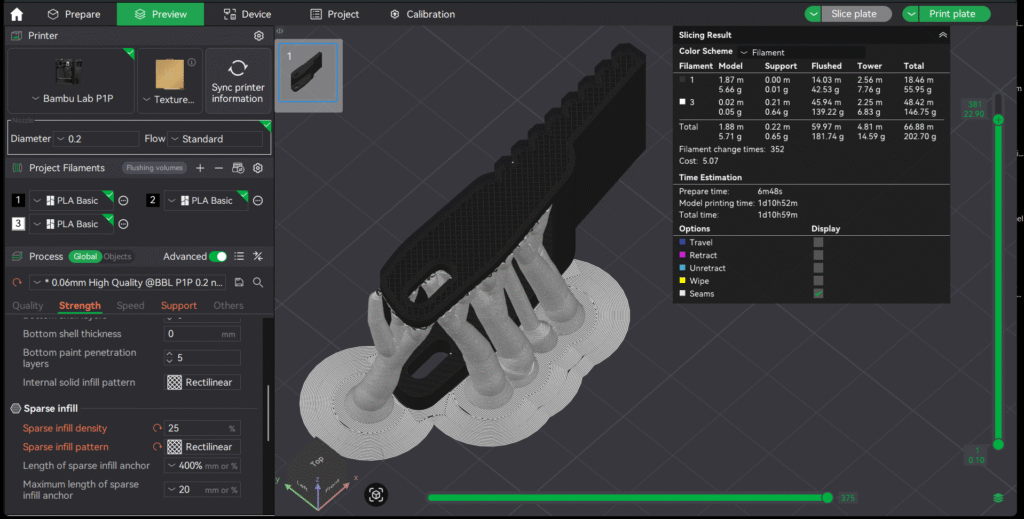

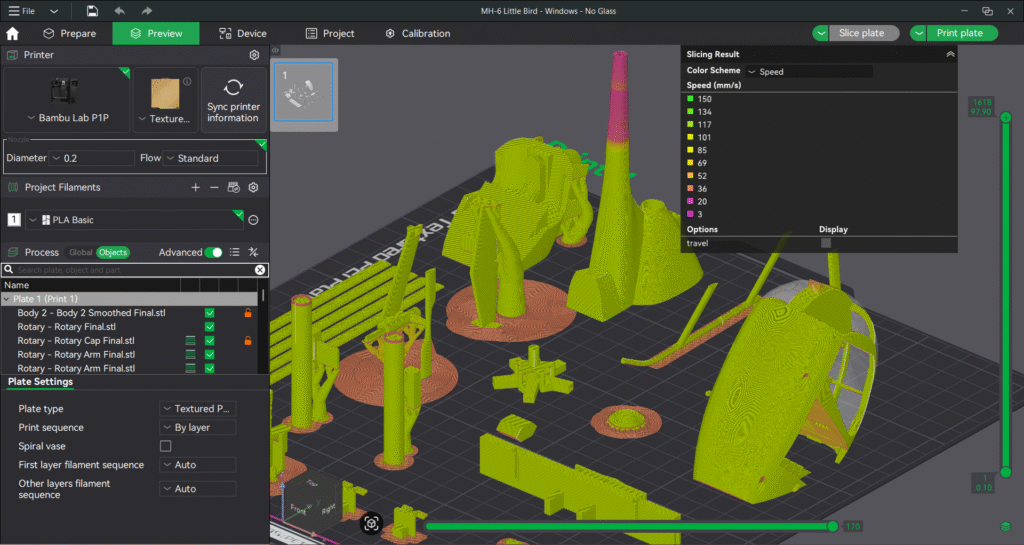

Technical Preparation and Checks

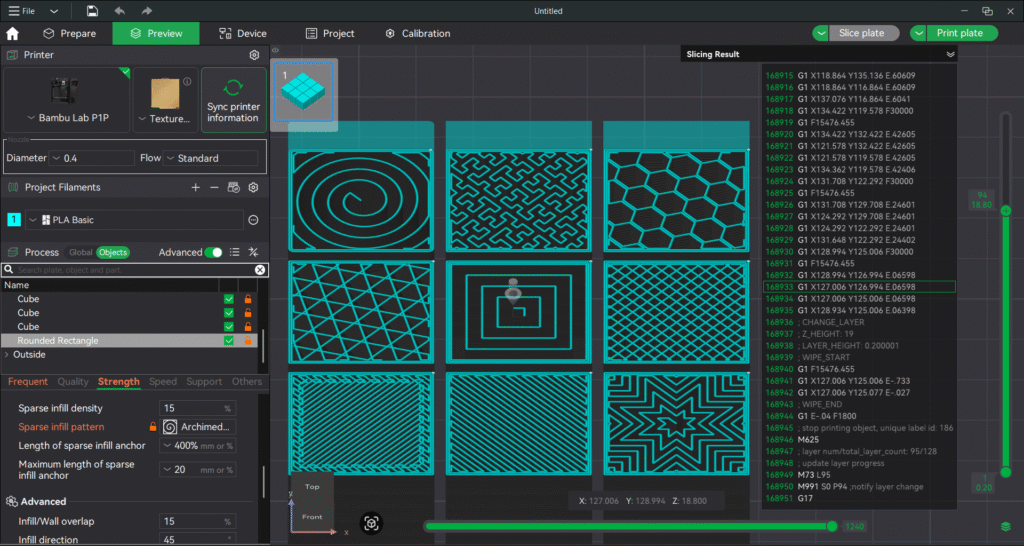

We then proceed to the technical preparation of the model in slicing software. This is where we define all the manufacturing parameters:

layer height,

thickness of external and internal walls,

density and structure of the infill,

printing speeds, temperatures, layer sequencing,

generation of supports if necessary,

optimal orientation of the piece to ensure its strength and finish.

Each parameter is adjusted based on the material used, the geometry of the part, and the mechanical or aesthetic requirements of the project.

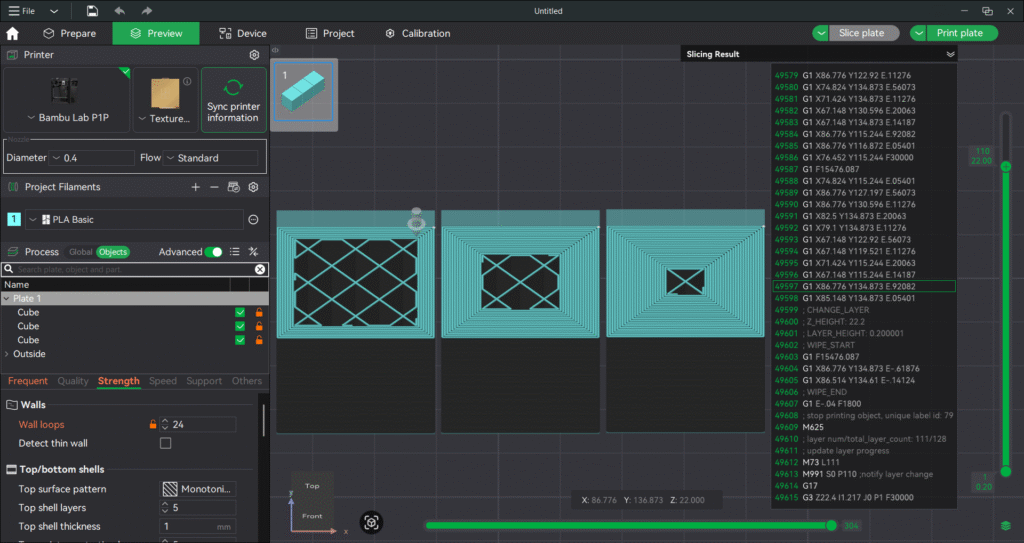

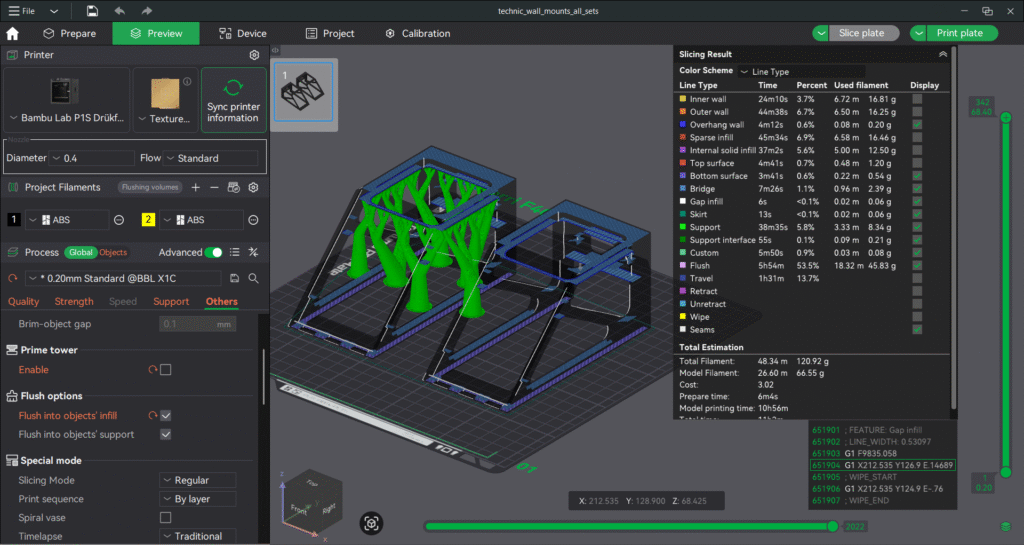

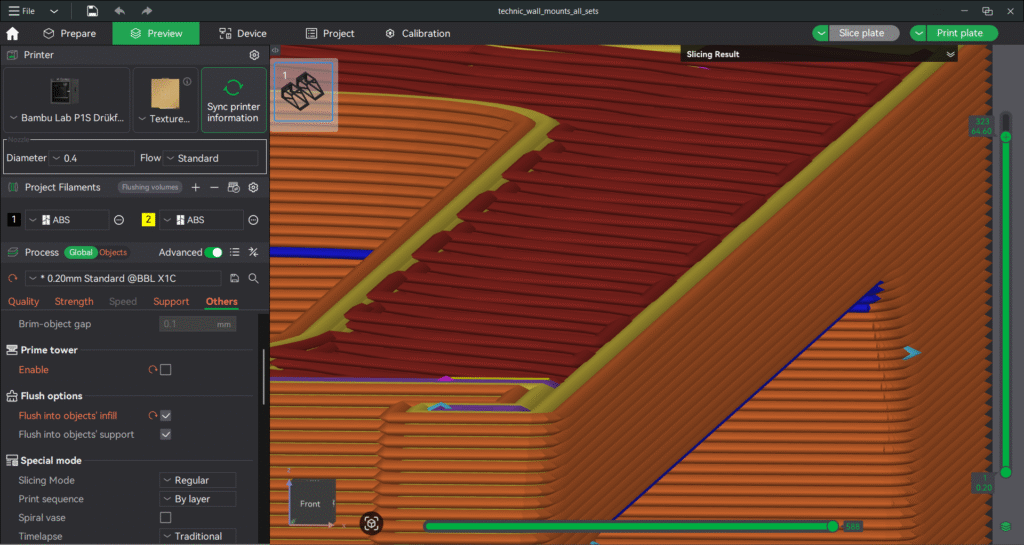

Optimization and validation of the G-code

Once the G-code is generated, we carry out a manual review and verification:

Layer-by-layer simulation of the print to detect potential defects

Checking the estimated time and filament consumption

Identifying critical points (extreme overhangs, areas sensitive to retraction, thermal transition zones)

Final adjustments, if necessary, before approving the file for printing

A mastered technical approach

At Drükfab, print quality is the result of a comprehensive, rigorous, and perfectly mastered process that combines both mechanical and digital work.

On one hand, our printers benefit from meticulous maintenance and constant checks, ensuring exemplary stability and repeatability. On the other, our digital expertise allows us to design, analyze, and prepare each part with precision.

Thanks to this dual demand — technical and methodological — every print we produce is reliable, reproducible, and consistently high quality. Nothing is left to chance: every detail, visible or invisible, is treated with the same level of rigor.

At Drükfab, every printed piece is much more than an object: it is the outcome of a high-level technical process designed to meet the most demanding expectations.